Grayslake, Ill., March 20, 2025 — Unique applications often require some outside-the-box thinking. That certainly was the case when the owners of a business located in a downtown Denver office wanted metal ceiling panels as a part of their unique design.

As a business focused on helping customers create their own office space, Workplace Resource wanted to create a flexible showroom to work with its clients. That space included metal ceiling panels fabricated by Sheet Metal Supply.

“The front and core of our new space is meant to inspire and be a place of gathering for our team, the clients we serve and the community we support and connect with,” says Madeline Sapyta, Creative Studio Director at Workplace Resource. “The front of our showroom can be flipped from a series of lounge settings to a 100-seat lecture or panel discussion space and we wanted the finishes and the overall space to invoke emotion and inspiration.

“The goal of the ceiling, in particular, was to create an element that helped define the otherwise very open and flexible entertaining space we were wanting. The high reflectivity and texture of the material created movement and drama in the space, allowing light to play off it.”

Sapyta says the light and reflective material allows for a lower ceiling height to be successful in defining the space as well as the overall impact it has on those interacting in the space.

“Gensler Architecture and Workplace Resource came up with the concept to utilize stainless steel ‘pebbled’ rolled metal sheets from Rigidized Metals (Corporation of Buffalo, N.Y.),” says Dan Parker, project manager at SRB Acoustics of Denver. “When we were hired by (general contractor) i2 Construction, we contacted Rigidized Metals to find out what they had in mind for this ceiling and they referred us to Sheet Metal Supply to bend the stainless into ceiling panels.

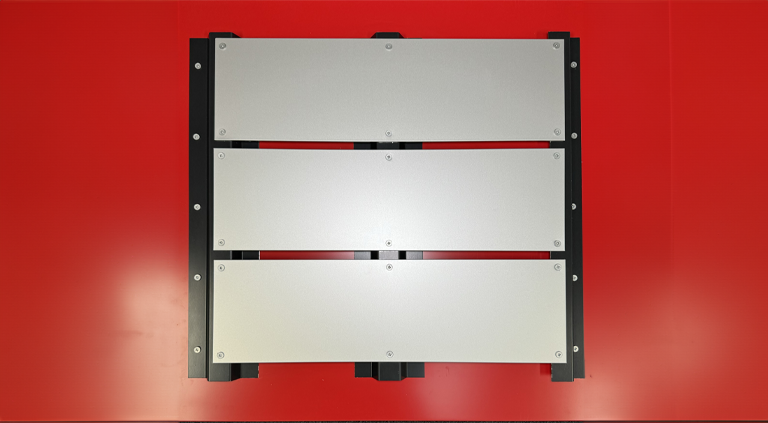

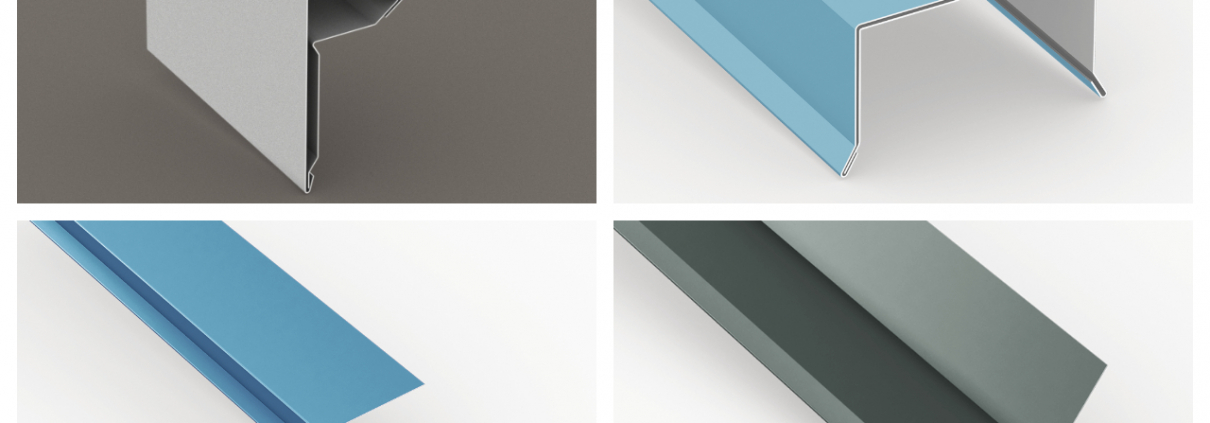

“SMS produced a great design to make these flat panels into a ceiling tile. Their design added substantial integrity to a ‘floppy’ panel and the design allowed us to make an accessible attachment to the Armstrong Heavy Duty Grid above. As the metal is available in 48-inch widths, this ceiling was comprised of 45-inch panels to allow for the custom bends on all sides.”

Rigidized Metals textured the stainless steel, creating a product it calls its Pattern 1WND, a rolled pattern named to evoke the appearance of “Wind on the Water.” Rigidized Metals offers sheets up to 48 inches wide and 12 feet long.

“We worked together with Sheet Metal Supply to create mockup panels that were reviewed by Workplace Resource, Gensler and i2 Construction,” Parker says. “Once approved, we created CAD drawings of the space, based on field measurements, installed the uniform sized ‘field panels,’ then made measurements for the final ‘non-standard’ panels accurate to 1/16th of an inch. Those panels were created by Sheet Metal Supply and shipped to us.”

The decision to have Sheet Metal Supply fabricate the panels improved lead times by weeks, maybe months, Parker says.

“Had I been dealing with a manufacturer of ceiling panels with this type of material, this process would have taken much longer,” Parker says. “Field measurements are usually given to the manufacturer so they can create shop drawings, which takes six weeks; we have them reviewed, which takes another two weeks; and then place the product into production, which could take another 12 weeks. Add to that another six weeks to correct everything they screwed up and this is best-case scenario.

“SMS turned around our field measurements into shop drawings in a week and had panels produced in four weeks.”

Parker says this is the only time in 30 years he has experienced 100 percent accuracy with these types of panels and these lead times. He says SRB employees made some mistakes during installation and some adjacent surfaces moved between measurements and delivery of the panels. SMS was able to create replacement panels quickly.

“This was the first larger scope project using our new 1WND pattern,” says Steve Valdespoino, Director of Business Development Architectural Products at Rigidized Metals. “Lead time was a big challenge, but because we are a domestic manufacturer, we were able to meet all requests. We have a good relationship with SMS and have collaborated on various projects.”

Fabricating the stainless steel ‘pebbled’ rolled metal sheets was a unique assignment for Sheet Metal Supply, but proper planning and new equipment played a large role in the success of the project.

“The aerospace precision and capability of the laser allows it to cut this textured material perfectly, as it has proximity sensors to keep the head floating over the material at the proper height for a very precise and perfect cut,” says Ben Kweton, president at SMS. “Working with a mirror-polished stainless steel material, there is basically no margin for error in fabrication. That means the material must get through the laser without any surface damage and it must get through the press brake. Thankfully, our investment in state-of-the-art equipment didn’t stop at the laser. The Safan press brakes with their European precision ground tooling and non-marking accessory cloth assured perfect results.”

SMS project manager Zach Timmerman was responsible for heading up communication to help make the architect’s concept become an achievable reality. The fabrication process at SMS along with the SRB Acoustics installation team, led to successful completion of this unique project.

“We had to play with a few different designs to ensure the smoothest installation as well as an efficient usage of material,” Timmerman says. “We worked with Rigidized Metals to optimize sheet sizes based on our panel sizes, allowing us to eliminate as much waste as possible. Everyone is very happy with the end result on this project.”

Check out more photos from this project here.

About Sheet Metal Supply

Founded in 1991, Sheet Metal Supply Ltd. is North America’s premier zinc fabricator as well as a leading fabricator/supplier of custom-formed perimeter edge systems, wall facades, flat lock tiles, substructural components, ES-1 rated products, glazed-in panels, standing seam, ACM/MCM/plate panels and much more. The company ships internationally and is regarded for its high-quality products and quick turn-around. For more information, visit www.sheetmetalsupplyltd.com.

Architect: Gensler Architecture, Denver

Installer: SRB Acoustics, Centennial, Colo

General Contractor: i2Construction, Denver

Stainless Steel Supplier: Rigidized Metals, Buffalo, N.Y.

Fabricator: Sheet Metal Supply LTD, Grayslake, Ill.

Owner: Workplace Resource, Denver

Photographer: ©Jason O’Rear

Completion Date: September 2024